The combination of stable processes with high process capability and consequent monitoring of the production process leads to a low error rate. We account for the process capability by means of the SPC method and by determination of the Cpk and Ppk values. This monitoring is not limited to the short-term values during the series production start-up. It also serves as evidence for the productions long term capability.

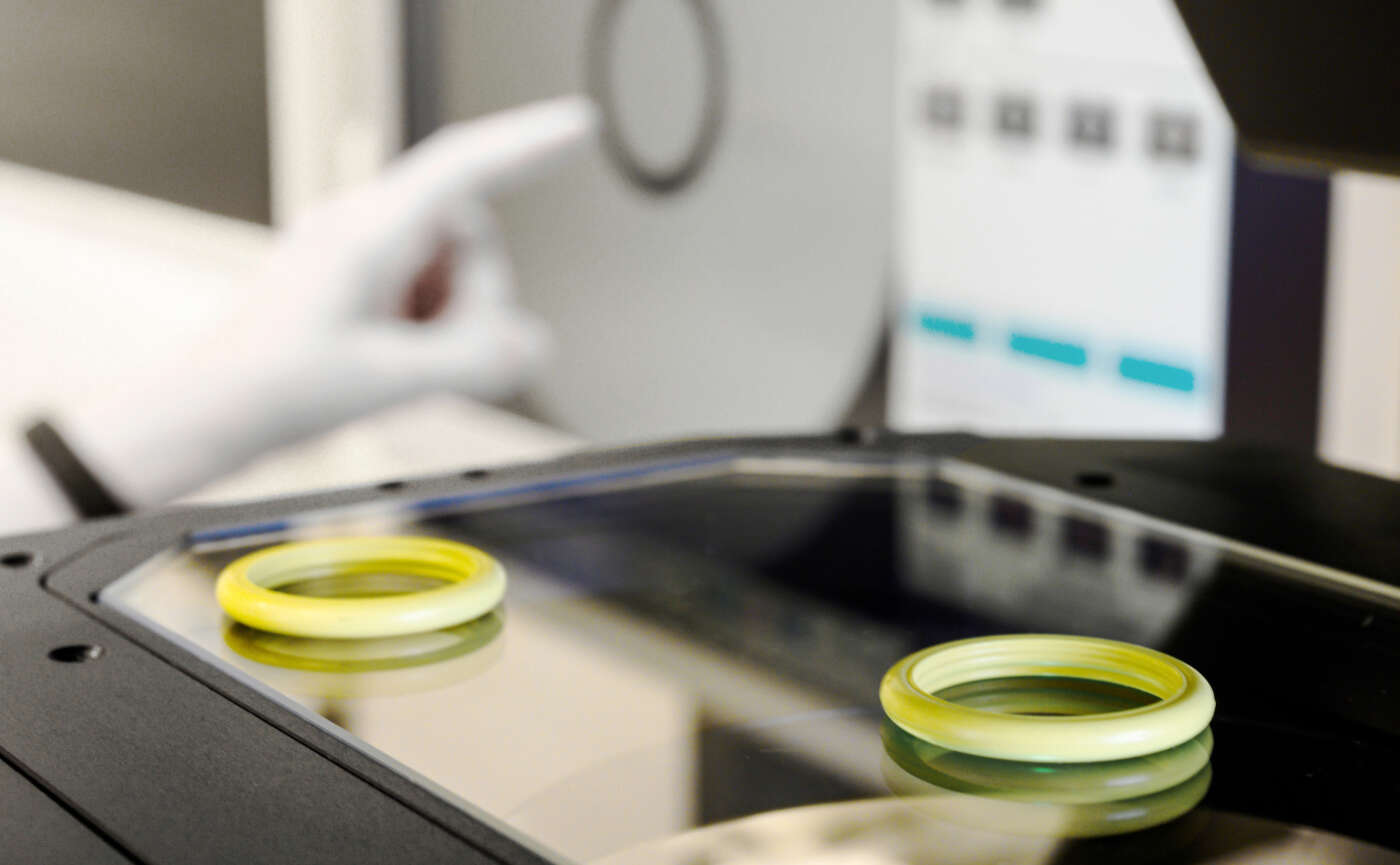

We are committed to a zero defect strategy and follow the objective of keeping down the ppm rate as low as possible. When requirements cannot be achieved reliably by process design, we employ a 100% inspection. Machine sorting is accomplished by opto-electronical control. We conduct this special sorting as in-house service and also subcontract to external facilities. Certain features are either only verifiable through machine sorting using disproportional efforts or not feasible at all. In such cases we resort to a 100% manual and visual control.